The Story of the Lanchester Forty

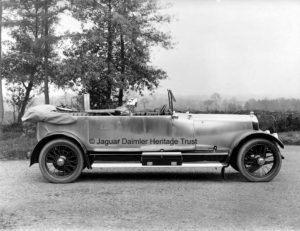

A polished aluminium Lanchester Forty Tourer, circa 1920/21, with rear screen erected to protect the passengers.

The two mid-mounted spotlights are on swivel arms.

The Lanchester Motor Company was formed by three brothers, Frederick, George and Frank, all of them remarkable and able engineers, with Frederick as the leading light. He was experimenting with powered flight and motor boats in the early 1890s and built their first motor-car in 1895.

It must be noted that this was designed from the start as a car, not as a horseless carriage, and it ran on the public roads in March 1896. It had a single-cylinder 1,306 cc engine with the piston having two connecting rods to separate crankshafts and flywheels rotating in opposite directions giving very smooth running. A two-cylinder engine was fitted to the same chassis in 1897 and a second complete car was built alongside it.

This led to the first Lanchester production cars in 1900, when six were made for demonstration to potential agents and customers. They were fitted with two-cylinder 4,033 cc horizontal air-cooled engines, retaining the twin crankshaft design. Steering was by a side-mounted lever or tiller.

Other models followed and the marque was established as a major manufacturer of quality cars. World War One saw Lanchester supplying vehicles, including armoured cars, to the War Department. When the Armistice was signed in 1918, all government contracts were cancelled, and Lanchester was just one of the many suppliers who found themselves in a difficult position. Many businesses were forced to close or find different products with which to continue, but Lanchester, with the aid of a government settlement payment of £180,000 (about £4 million in today’s values), was in a strong position to continue as a motor manufacturer.

Post-war Demands

During the war-years the car business had been limited to existing models for use by the military and very little had been planned for the post-war market. However, as the war neared its end, work began on a new design, this was not ready when peace did come but it was quite advanced. Pre-war Lanchesters were quite unlike their rivals’ models, with their engines mounted in the front footwell between the driver and the front-seat passenger. There was no conventional long bonnet to speak of, though Frederick Lanchester had introduced this layout on the four-cylinder ’20’ in 1904. However, he was increasingly at odds with his fellow directors and resigned as chief designer. After a period of acting as a technical consultant, he left the Lanchester Company. In 1913 his brother George, who had worked alongside Frederick, took over as chief designer.

The following year, just before the outbreak of war, Lanchester had announced the Sporting Forty, which had been designed by George. This was a smart-looking model but was let down with the use of a side-valve six-cylinder engine and semi-elliptic rear springs, both of which were considered retrograde steps when compared with the Lanchester models that had preceded it. However, the 1914 Forty set many of the standards for the post-war Forty, including the long bonnet. Lanchester had no new model to show when sales resumed in 1919 and the catalogue of the time contains photographs of pre-war Lanchesters.

George Lanchester set to work using the Sporting Forty as a starting point; the pre-war chassis was improved and an all-new up-to-date engine was designed. The pressed-steel chassis had substantial side members and the area around the engine and gearbox was enclosed to make a box section. To provide additional rigidity the engine and gearbox bearers were bolted directly to the chassis, which made use of several cross members to give additional strength.

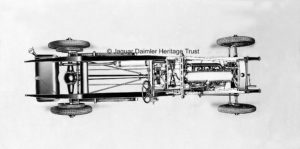

A 1919 plan-view of the Forty chassis showing the layout of the engine, steering and rear-wheel brakes.

Keeping to the pattern of the time, Lanchester used heavy duty semi-elliptical front springs, but reverted to the pre-1914 Lanchester cantilever suspension at the rear. Depending on the weight of the chosen coachwork, different spring sets were available. These spring sets were developed by Lanchester and were quite different from anything else on offer at the time. Many other manufacturers bought in standard sets for use on their cars but George Lanchester decided that a dedicated system was better.

Nothing was left to chance, brass inter-leaves loaded with lubricant were fitted between the polished spring leaves, and the whole assembly was then enclosed in a leather case. The spring ends were located by means of phosphor-bronze rotating trunnions with four steel rollers in each.

The open Forty Tourer could be converted into a closed car by raising the roof and fitting the removable window panels.

What appear to be opening quarter-lights on the doors are actually flaps to allow access to the internal door handles as the car had no external handles.

Add to this the improved rear axle that was allowed to pivot radially from a large spherical joint at the front of the propeller shaft, which was enclosed in a torque tube, and the already efficient design was further enhanced. Addressing the sideways movement of the rear axle, Lanchester added diagonal tie-rods from the suspension spring brackets to the front of the torque tube. By the time Lanchester had completed work on the front and rear suspension, he had made a most efficient and smooth system that became the envy of rival manufacturers.

Lanchester used a straight front axle secured on top of the springs. The front wheel hubs were mounted on roller and ball bearings and the rear axle drive housings had bolted to it steel tapering casings and ‘fully floating’ wheel hub mountings. Newly-developed 15-inch brake drums were fitted to the rear wheel hubs, to which Rudge-Whitworth wire wheels were fitted to the outer splines.

Alternatively, many examples of the Forty were fitted with steel disc wheels, attached to the hub by six studs.

Lanchester Forty Engine

George Lanchester and his team designed a new engine that owed very little to the Sporting Forty of 1913-14. As he had started with a clean sheet he was able to incorporate elements from other engines of the time. For example, the use of an overhead camshaft was probably inspired by some of the aero engine designs that had emerged during the war years, but most of the other features of the new unit came from George Lanchester’s fertile mind. Another innovation worthy of note was the robust 2.5 in diameter hollow chrome-nickel steel crankshaft that was supported by seven main bearings, something that was not usual for the day.

A 1922 Forty five-seat Landaulette with coachwork by Lanchester for Lionel Rapson, a well-known tyre producer and racing driver. Rapson also had a special-bodied 40 hp made for tyre-testing and racing at Brooklands.

The new model was called the Lanchester Forty to indicate the horsepower of the 6,178 cc engine, but this was, in fact, 38.4 hp as rated by the Royal Automobile Club. However, in marketing terms Lanchester 38.4 does not sound quite as attractive as Lanchester Forty; especially when Rolls-Royce offered a 40/50 model.

The Lanchester engine had a single overhead camshaft and was a straight six-cylinder, cast in two blocks of three. It had a bore of 4 ins and a stroke of 5 ins. Two spark plugs were fitted to each cylinder; one suitable for the Remy high-tension coil and battery system and the other suitable for the magneto installation. The distributor was located at the forward end of the camshaft, with the flange-mounted magneto being driven by a gear on the drive for the vertical camshaft. The connecting rods were produced from high-tensile steel and were machined to achieve identical balance. Detachable cylinder heads were not fitted, but detachable inlet valve cages made it possible to remove the tungsten steel valves, which were designed to be removed with little difficulty.

A tank mounted at the rear of the chassis held the petrol, and an Autovac (vacuum operated pump) supplied the single Smiths four-jet carburettor, which was mounted low on the right of the engine block.

Lanchester had designed the engine with the two innermost pairs of cylinders sharing a common port, and separate ports for the cylinders at the front and rear, so four inlet pipes – not six – supplied the petrol/air mixture to the combustion chambers. Careful design ensured that each cylinder obtained an equal amount of petrol vapour, contributing to a smooth-running engine. Considering that work on the new model had only commenced in November 1918, it is a credit to Lanchester and his team that a working prototype was ready for road testing by August the following year. In fact two cars had been made ready, a four-seat saloon and a five-seat open tourer.

On the Road

George Lanchester’s new Forty Tourer was heralded by the Press when it was made available for testing. They were enthusiastic about the ‘smooth ride and engine performance’ and recorded figures of a top speed of 78 mph (125 k/hr); acceleration from 10 mph to 30 mph (16-48 k/hr) was achieved in eight seconds and the car would ‘quite happily motor at low speeds in top gear.’ One writer claimed at top speed of 85 mph (137 k/hr). It was the acceleration that was noted by many writers, one of whom stated: ‘…for a heavy car it is as lively as a small sporting model and has terrific acceleration.’ Another commentator suggested that although the Lanchester was expensive, it would repay one with refinement and to ‘…connect the Lanchester with purchase money is almost sacrilege.’ Another referred to it as a ‘supercar’ and said that he ‘…could not find a single thing about it that can by any stretch of the imagination be said to call for criticism’. Soon the Lanchester Forty was given the title of ‘The Finest Car in the World’. Magazines from The Motor to Country Life, all tested the car, which was most probably the same example, and it appears to have performed faultlessly; no negative reports were made in any of the publications.

The Forty goes on Sale

This extraordinary Forty was built on a special 14 ft 10 in long chassis for the Maharajah of Alwar in 1924. He ordered it from the Lanchester showrooms in New Bond Street and specified the fittings that were required.

At the London Motor Show in November 1919 at Olympia, the prototype Lanchester Forty Saloon was shown to the public for the first time. The car had been carefully prepared for its debut and had been given a sumptuous interior, with well-upholstered seats, deep-pile carpets and silver fittings; the door panelling was of walnut and the blinds were silk.

Priced at £2,400 it was the most expensive car at the Show. Orders were forthcoming and production commenced on the two models at the Lanchester factory in Birmingham.

Various body styles were offered by the coach-builders of the day and to accommodate different styles the wheelbase of the Forty could be extended but the track (4 ft 10 ins/1,473 mm) remained the same.

The craftsmanship from Lanchester is seen to advantage in this close view of the Maharajah of Alwar’s State Landau. The interior was of gold silk brocade and the lamps and interior fittings were of silver.

Seen to advantage is the mirror-like paint finish with the photographer clearly reflected!

No mechanical modifications were made until 1921 when the Smiths carburettor was replaced by an SU model but this was found to be less efficient and a change back to Smiths was made in 1923.

For the 1921 Motor Show, Lanchester displayed three examples of the Forty; a five-seat tourer (£2,750), a seven-seat Limousine (£3,000) and a rolling chassis at £1,950.

Nearby on the Thrupp & Maberly Coachworks stand a Lanchester Forty with a four-seat Limousine body was on display with a price tag of £2,746.

To gain sales, George Lanchester visited the United States in 1921 and Brewster were appointed as agent, selling their first Forty to Henry Ford. Lanchester was the first British car manufacturer to offer a left-hand-drive version of their models. Twenty rolling chassis were exported and Brewster manufactured the body as required. This, however, was a short-lived partnership as Rolls-Royce purchased Brewster in 1924 and ended Lanchester sales. However, Lanchester found other markets in Europe and in the British Empire but business in the UK was not as good as had been hoped.

The economy of the country following the recent War was fragile and to try and boost sales Lanchester cut their prices; the chassis was £1,800, a Tourer £2,300 and a three-quarter Landaulette at £2,600. When the Forty first appeared it had rear-wheel braking only, something that was quite usual at the time, but for the 1924 Motor Show Lanchester offered four-wheel braking as standard. To do this the front axle had to be redesigned to accommodate the new drums housing rod-operated Ferodo-lined brake-shoes. Also revised were the rear drums; they were now double width to take separate pairs of shoes for the foot brake and the hand brake. To make life easier for the chauffeur/driver, George Lanchester designed a hydraulic servo system for the brake foot, which was fed by high-pressure oil from a gearbox oil pump.

A 1923 Lanchester-bodied Forty Tourer with the hood in raised position. HRH The Prince of Wales (later King Edward VIII) owned a similar model which he used extensively. The rest-stay for the hood when folded is visible on the rear body.

Changes were also made to the engine, which was virtually redesigned; the layshaft was removed and both the starter motor and dynamo relocated. A redesigned camshaft now drove the horizontally-mounted distributor which protruded through the centre of the valve cover. The oil pump was moved to the rear of the engine and was driven by a worm-drive from the crankshaft. The copper inlet manifold was replaced with a new-design cast aluminium example that was water-heated. The engine was now more powerful, more responsive and quieter.

Though the Lanchester did not sell in the same numbers as models from rivals Rolls-Royce and Daimler, they did have a loyal following and were given a tremendous boost when HRH The Duke of York (later HM King George VI), purchased a Lanchester Forty in 1925. He was pleased with the car and remained a Lanchester-man for the rest of his life, even when Lanchester became a badge-engineered Daimler he insisted that his Daimlers were built with Lanchester radiator grilles and badges.

The Duke of York was not the only Royal to select Lanchester. Abroad the special coachwork car was in demand and in India some wonderful and exotic versions graced the Forty chassis. These were built in the UK with every luxury and labour-saving device then available, and shipped complete in large wooden crates. Obviously the Lanchester coped with the uneven roads of India in the 1920s; one keeper of vehicles, to the Maharajah of Nawanager, wrote to the Company about three Lanchester 40 models in his care. ‘They have been run over 60,000 miles under all sorts of conditions in India and England. It would interest you to know that I have a fleet of over 60 high-grade cars of different makes, including Lanchesters etc. therefore I am in a fair position to judge their merits. The Lanchester is easily the best car I have under my care.’

Further improvement came when Dunlop and Lanchester worked together to develop a new wheel and tyre combination for the heavy car. These were introduced in 1925 and were further improved the following year when low-pressure ‘balloon’ tyres made their appearance. While the various improvements made the Forty much better, sales fell and in 1926 only sixteen examples were sold. The following year that number fell to ten cars and in 1928 when just a handful were made the Forty was dropped from the Lanchester line-up. The Forty had served its purpose; George Lanchester had been working on a 30 hp straight-eight engine and this would be the next big car from the remarkable Lanchester Motor Company.

Author: François Prins

© Text and Images – Jaguar Daimler Heritage Trust